UBTech’s Walker S2 marks a leap towards uninterrupted robotic work

The Walker S2 humanoid robot can swap its own battery, enabling 24/7 continuous operation.

The paradigm of robotic autonomy is undergoing a profound transformation with the advent of UBTech’s new humanoid, the Walker S2. Traditionally, robots have been tethered to human assistance for power, requiring manual plugging in or lengthy recharges.

UBTech, a pioneering robotics company, is now dismantling these limitations with a groundbreaking feature in the Walker S2: the ability to swap its battery autonomously. The innovation promises to reshape the landscape of factory work and potentially many other industries, enabling near-continuous, 24/7 operation without human intervention.

The core of this advancement lies in the Walker S2’s sophisticated self-charging mechanism. When a battery begins to deplete, the robot does not power down. Instead, it intelligently navigates to a strategically placed battery swap station.

Once positioned, the robot executes a precise sequence of movements: it twists its torso, deploys built-in tools on its arms to unfasten and remove the drained battery from its back cavity, places it into an empty bay on the swap station, and then expertly retrieves a fresh, fully charged module.

The new battery is then securely plugged into one of its dual battery bays. The process is remarkably swift, taking approximately three minutes, allowing the robot to return to its tasks almost immediately.

The hot-swappable system mirrors the convenience of advanced electric vehicle technology, but its application to humanoid robotics unlocks unprecedented operational efficiency. Standing at 5 feet, 3 inches (approximately 160 cm) tall and weighing 95 pounds (about 43 kg), the Walker S2 is designed to integrate seamlessly into environments built for humans.

It has two 48-volt lithium batteries, ensuring a continuous power supply during the brief swapping procedure. While one battery powers the robot’s ongoing operations, the other can be exchanged.

Each battery provides approximately two hours of operation while walking or up to four hours when the robot stands still and performs tasks. The battery swap stations are not merely power hubs; they also meticulously monitor the health of each battery.

Should a battery show signs of degradation, a technician can be alerted to a timely replacement, further optimising the robot’s longevity and performance.

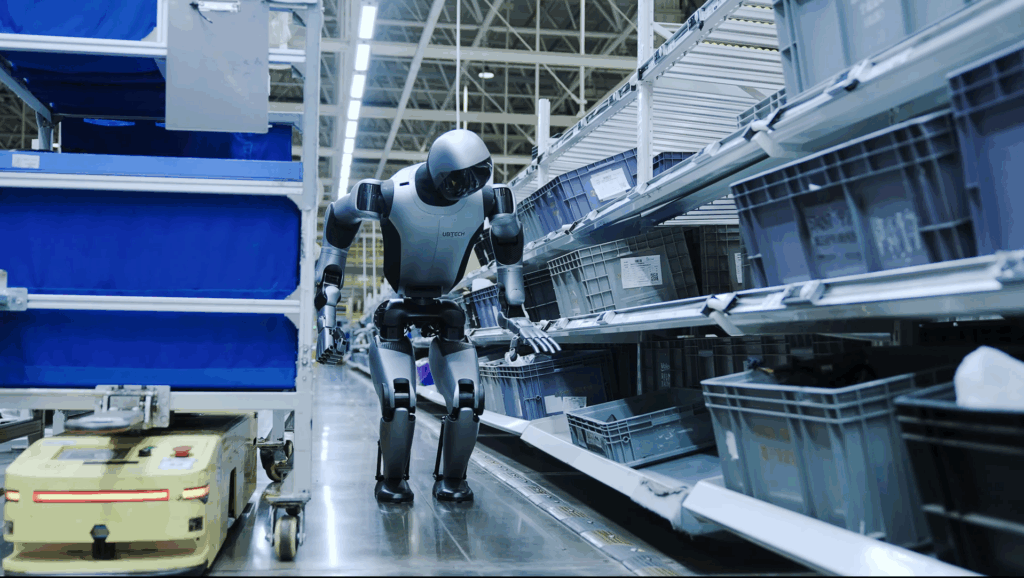

UBTech claims the Walker S2 is not a mere laboratory prototype but a robust solution engineered for real-world industrial deployment. Extensive testing has been conducted in the highly demanding environments of car factories operated by major Chinese electric vehicle manufacturers, including BYD, Nio, and Zeekr.

The trials validate the robot’s ability to operate effectively in dynamic production lines. The Walker S2 incorporates advanced vision systems, allowing it to detect battery levels and identify fully charged units, indicated by a green light on the stacked battery packs.

The robot autonomously reads the visual cues, ensuring precise selection and connection via a simple USB-style connector. Furthermore, the robot features a display face, enabling it to communicate its operational status to human workers, fostering a collaborative and transparent work environment. For safety, a prominent emergency stop button is also integrated.

China’s strategic investment in robotics is a driving force behind such innovations. Shenzhen, UBTech’s home base, is a thriving hub for robotics, boasting over 1,600 companies in the sector.

The nation’s broader push towards automation, part of its ‘Made in China 2025’ strategy, is a clear statement of global competitiveness, with China betting on AI and robotics to spearhead the next manufacturing era.

The coordinated industrial policy has led to China becoming the world’s largest market for industrial robots and a significant innovator in the field. The implications of robots like the Walker S2, built for non-stop operation, extend far beyond traditional factory floors.

Their ability to manage physical tasks continuously could redefine work in various sectors. Industries such as logistics, with vast warehouses requiring constant material handling, or airports, where baggage and cargo movement is ceaseless, benefit immensely.

Hospitals could also see these humanoids assisting with logistical duties, allowing human staff to concentrate on direct patient care. For businesses, the promise of 24/7 automation translates directly into increased output without additional human resources, ensuring operations move seamlessly day and night.

The Walker S2 exemplifies how advanced automation rapidly moves beyond research labs into practical, demanding workplaces. With its autonomous battery-swapping capability, humanoid robots are poised to work extended hours that far exceed human capacity.

The robots do not require coffee breaks or need sleep; they are designed for relentless productivity, marking a significant step towards a future where machines play an even more integral role in daily industrial and societal functions.

Would you like to learn more about AI, tech and digital diplomacy? If so, ask our Diplo chatbot!