BASF and Nanotech Energy to produce lithium-ion batteries using recycled materials

The goal is to establish a closed-loop system and produce batteries with locally recycled content.

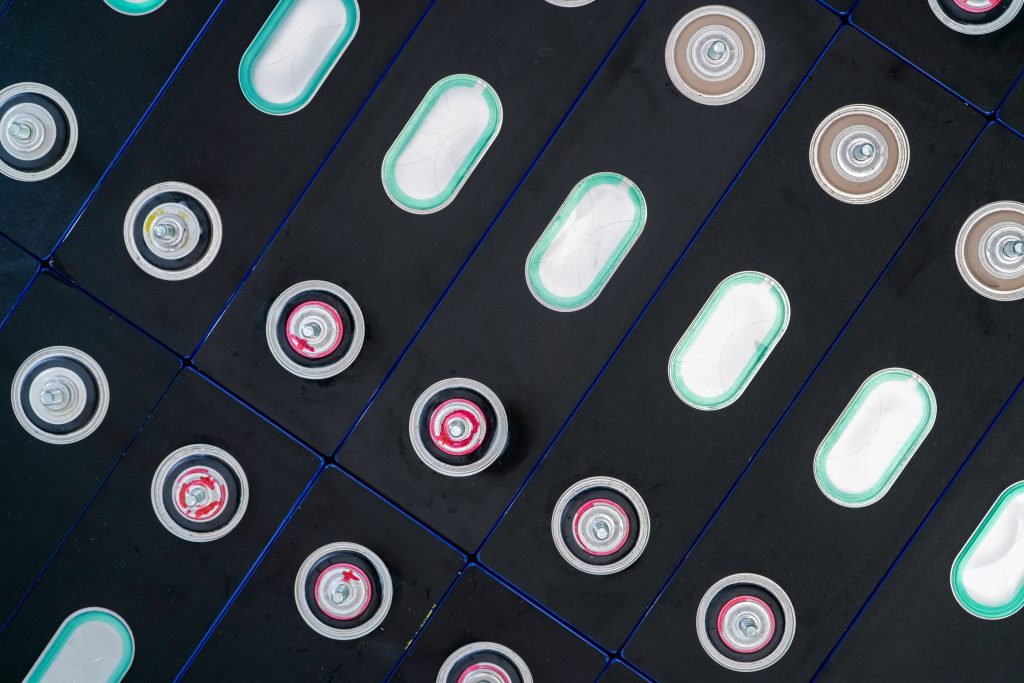

Chemical company BASF has partnered with Nanotech Energy, a manufacturer of graphene-based energy products, to produce lithium-ion batteries using recycled materials. This collaboration aims to promote sustainability and reduce the carbon dioxide (CO2) footprint associated with battery production. BASF will create the cathode active materials using recycled metals from a Battle Creek, Michigan facility. In contrast, Nanotech Energy will use these materials to manufacture lithium-ion battery cells, thus completing the closed-loop system.

According to BASF, using recycled metals in battery production can reduce the CO2 footprint by approximately 25%. The Biden administration has been working to build out the US lithium battery supply chain and recycling programs. In June, the Department of Energy announced it would provide $192 million in funding to promote battery recycling.

Why does it matter?

By establishing a closed-loop system in North America, the partnership enables the production of lithium-ion batteries that contain locally recycled content. This development supports the transition towards a more sustainable and circular economy, as battery materials are reused and recycled, reducing the reliance on virgin resources.